Electronics & Infotech

Reliable, efficient air filtration systems are essential for maintaining high performance and ensuring maximum safety, regardless of the energy source utilised for power generation. As energy generation is fraught with hazards, installing high-performance air filters ensures the protection of your plant and its employees and contributes to the continual operation of your business. This is true regardless of the harsh conditions present, such as the high temperatures of diesel or gas combustion or the extensive safety concerns surrounding nuclear power generation.

"Data centres must be cooled to a specific temperature, and the physical equipment must be protected from the elements to avoid costly breakdowns and for smooth operations. The most pertinent issue to the sustainability of a data centre is the corrosion of electronic components, which can directly lead to mechanical or system failure. Spectrum filtration provides solutions to avoid the impact of gaseous contaminants and pollutants to avoid corrosion of key electrical components that can cause electrical shortages, discharges and physical deterioration of equipment."

With the ever-increasing demand for semiconductors, the need for efficient and failure-free manufacturing is a must. Micro-contamination can cause a huge problem in the manufacturing process of semiconductors, micro and nanoelectronics. Spectrum offers best-in-class products including pre-filter, HePA & ULPA filter, molecular filtration as well as equipments like Fan Filter Units.

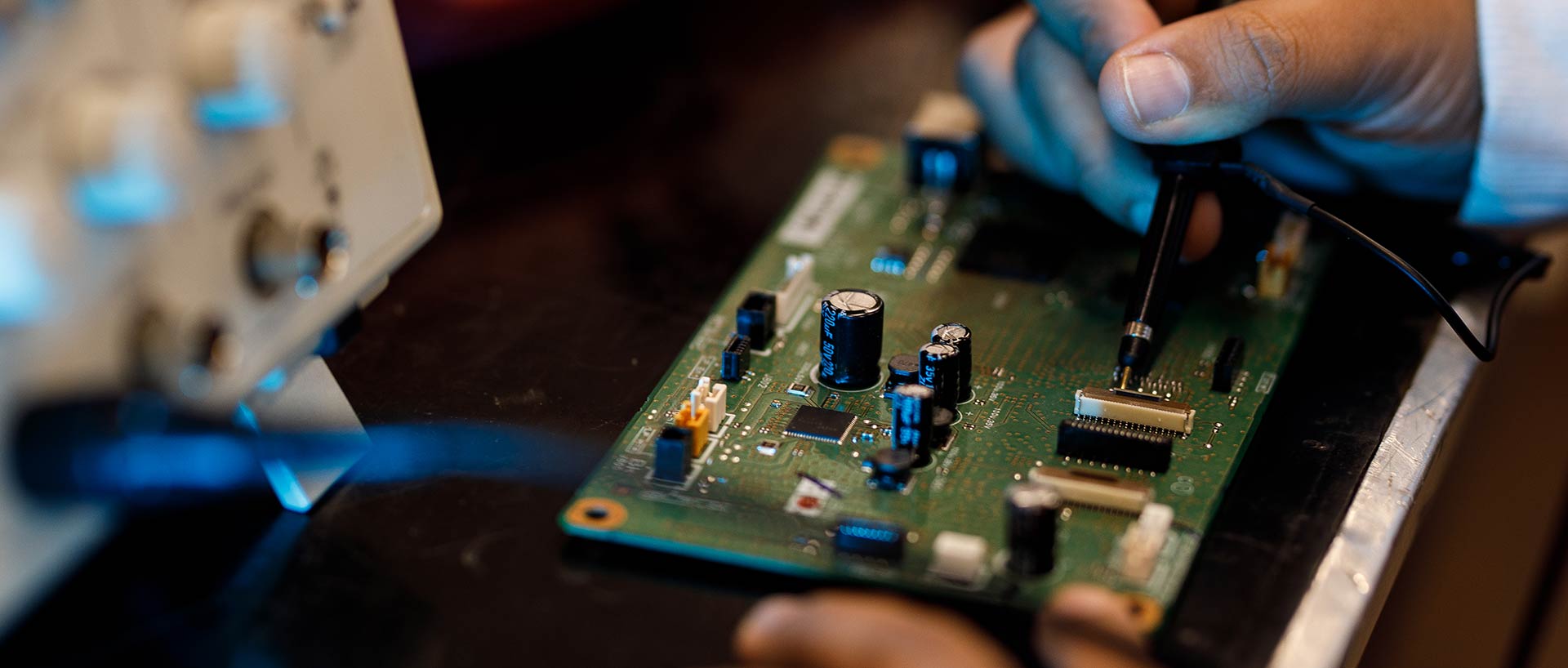

PCBs are sensitive electronic equipment that are very susceptible to corrosion. 75% of micro-electronic failure is caused due to corrosion. The impact of Nox, Sox and otherVOCs along with humidity and given the poor air quality in most cities and industrial areas makes equipment very suseptible to corrosion. It is especially worse in areas with close proximity to landfill sites, sewage drains and excess vehicular exhaust. Spectrum carbon filters and media helps ensure consistent uptime through shielding the electronic equipment from corrosive gases.

Electronic display market is growing rather fast and the need to manufacture higher resolution displays in the most cost-effective manner has become a key priority. Because of the huge size of the manufacturing plant, contamination control and energy saving becomes a major challange. Our HEPA and ULPA filters are quality inspected and ensure compliance to cleanroom air quality standards.

Optical devices are highly sensitive to dust particles. Contamination control technology helps protect your optical devices so you can drive better device performance. Air and gas-phase filtration keeps your processes safe from hazardous particles. Spectrum's cleanroom filters ensure particulate removal and saving energy costs.