Manufacturing & Materials

Manufacturing facilities always produce micron size airborne pollutants. These smaller particles are vital and harmful and thus pose a problem with regard to work and process safety. Heavy dust concentrations, molecular contaminants and combustible dust are examples of contamination which results in corrosive effects and flammability and may even be dangerous to both the environment and the workers.

Steel and iron plants are making significant investments in their plants to modernise their facilities. Air filters play a critical role in the steel industry by ensuring that the air quality in the production area is maintained at safe levels. There are several applications of air filters in the steel industry, including Blast Furnace, Electric Arc Furnace,Rolling Mills & Pickling Lines. We offer a wide range of filters, chemical media and recirculation units to suit the requirements of different areas in a steel plant to protect the people and machinery.

The use of air filters in the man-made fiber industry is critical to maintain air quality, protect workers' health, and prevent contamination of the final product. The industry involves the production of synthetic fibers like nylon, polyester, and acrylic, and the manufacturing process can generate various types of impurities that can be harmful to the environment . The production of synthetic fibers involves high-temperature processes that can generate particulate matter and fumes.Air filters are used at different stages of the manufacturing process, including the air intake to the manufacturing facility, before and after polymerization reactors and spinning machines, and in cleanrooms where a high degree of air cleanliness is required. The type of air filter used depends on the specific application and the impurities to be removed. For example, pre-filters and fine filters can remove larger and smaller particles, respectively, while activated carbon filters can capture odors and volatile organic compounds (VOCs), and HEPA filters can remove even smaller particles with high efficiency.

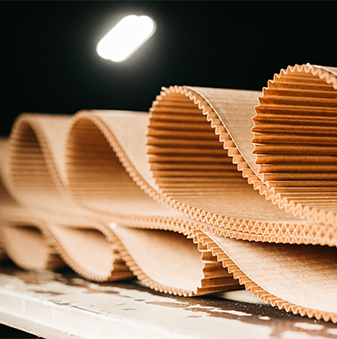

Air filters are commonly used in the pulp and paper industry to maintain air quality and prevent contamination of the final product. The industry involves various processes, such as wood preparation, pulp manufacturing, papermaking, and coating, which can generate impurities that can be harmful to workers and the environment. Air filters are used at different stages of the manufacturing process, including wood preparation, pulp manufacturing, papermaking, and coating. The type of air filter used depends on the specific application and the impurities to be removed. For example, pre-filters and fine filters can remove larger and smaller particles, respectively, while activated carbon filters can capture odors and volatile organic compounds (VOCs), and HEPA filters can remove even smaller particles with high efficiency.